Page 1 of 2

M201 - GTM32 Suggestions & Questions

Posted: Mon Jul 04, 2016 12:31 am

by greeffbf

I Bought a M201 - with the GTM32 controller via Banggood.

I bought this machine due to few reasons.

1 - GTM32 Controller can handle 3 extruders (No firmware to be found)

2 - Larger Print are 280 x 220

MODS

I replaced the lead screws with 8 x 2mm 4 groove and replaced the Z steppers with 0.9Deg 48mm Nema

I got rid of the flexible couplings on z axis drive to cut out slop. Your configuration make 2 heads not very accurate)

I modified the 2 in 1 head with 2 in 2 head.

I removed the fan on extruders at top. Useless.

I grinded down rod locks to provide maximum travel.

I modified Z axis end stop with lock nut to make more accurate.

I made PTFE tubes as short as possible to get more accuracy when withdrawing filament printing on 2 extruders.

Questions

1 - I use the GTM32-Dual extruder software and every now and then the LCD goes blank. Is this normal?

2 - Sometimes the print just freezes up at various fases of same job (Printing from SD card.) Sometimes prints fine, then freeze at 40 %, then at 67% never the same.

3 - It seems as heating bed element a bit weak to heat up aluminium bed fast. Can you not get higher wattage bed in same size?

4 - Can you please supply firmware so it can do 3 x extruders?

Suggestion

You have great idea but having firmware not accessible makes printer undesirable.

Re: M201 - GTM32 Suggestions & Questions

Posted: Mon Jul 04, 2016 4:42 pm

by syossi2

i with you.....i also put 3rd nozzle

i have 2 in1 and one saparte side by side

but .....

i also ask them to this 2 mounth ago....

that the firmware will recognize this 3 ports thermistor T2 , nozzle 2, extruder 2

and the 3 max end point to make them works and reconize by the firmware

hope they will do it soon

yossi

Re: M201 - GTM32 Suggestions & Questions

Posted: Mon Jul 04, 2016 4:47 pm

by William

greeffbf wrote:I Bought a M201 - with the GTM32 controller via Banggood.

I bought this machine due to few reasons.

1 - GTM32 Controller can handle 3 extruders (No firmware to be found)

2 - Larger Print are 280 x 220

MODS

I replaced the lead screws with 8 x 2mm 4 groove and replaced the Z steppers with 0.9Deg 48mm Nema

I got rid of the flexible couplings on z axis drive to cut out slop. Your configuration make 2 heads not very accurate)

I modified the 2 in 1 head with 2 in 2 head.

I removed the fan on extruders at top. Useless.

I grinded down rod locks to provide maximum travel.

I modified Z axis end stop with lock nut to make more accurate.

I made PTFE tubes as short as possible to get more accuracy when withdrawing filament printing on 2 extruders.

Questions

1 - I use the GTM32-Dual extruder software and every now and then the LCD goes blank. Is this normal?

2 - Sometimes the print just freezes up at various fases of same job (Printing from SD card.) Sometimes prints fine, then freeze at 40 %, then at 67% never the same.

3 - It seems as heating bed element a bit weak to heat up aluminium bed fast. Can you not get higher wattage bed in same size?

4 - Can you please supply firmware so it can do 3 x extruders?

Suggestion

You have great idea but having firmware not accessible makes printer undesirable.

Hi,my friend

Thank you for your suggestions,we are happy to hear that.

1.I think you can have a try to reset it on controller panel.

2&3.It is about the software and hardware,i'll feed it back to our engineer.

4.I'm afraid that we have no plan to update firmware temporarily for 3 extruder on M201.

Regards

Re: M201 - GTM32 Suggestions & Questions

Posted: Mon Jul 04, 2016 4:56 pm

by syossi2

its too bad,,,

its so easy just to enabled on firmware the

3 ports thermistor T2 , nozzle 2, extruder 2

pleaseeeeeeeeeeeeeeeeeeeeeeeeeeeee

Re: M201 - GTM32 Suggestions & Questions

Posted: Mon Jul 04, 2016 5:43 pm

by syossi2

hi greeffbf

can you explane with picture please the selected mods you have done please?

"

I replaced the lead screws with 8 x 2mm 4 groove and replaced the Z steppers with 0.9Deg 48mm Nema

picture please

I got rid of the flexible couplings on z axis drive to cut out slop. Your configuration make 2 heads not very accurate)

picture please

I modified the 2 in 1 head with 2 in 2 head.

picture please

I grinded down rod locks to provide maximum travel.

picture please

I modified Z axis end stop with lock nut to make more accurate.

?? i try to put also end stop . but the firmwre didnt activat it... so how did you do it?

"

thanks

yossi

Re: M201 - GTM32 Suggestions & Questions

Posted: Tue Jul 05, 2016 1:28 am

by greeffbf

Pictures as requested

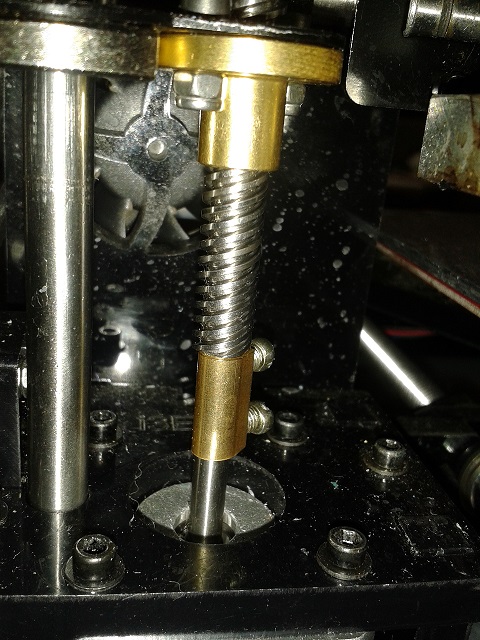

- Lead screw and 5mm to 5mm coupling, I turned the lead screw ends down to 5mm

- Lead screw Coupling.jpg (156.27 KiB) Viewed 14439 times

Lead screw and 5mm to 5mm coupling, I turned the lead screw ends down to 5mm

- Nema Stepper 0.9deg

- Stepper Nema09_48.jpg (126.8 KiB) Viewed 14439 times

Nema Stepper 0.9deg

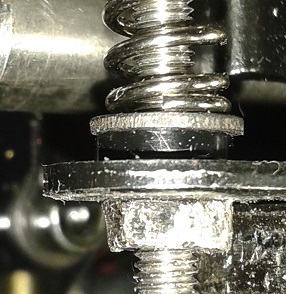

- Locknut on Z stop min

- Locknut on Z-min Stop.jpg (66.52 KiB) Viewed 14439 times

Locknut on Z stop min

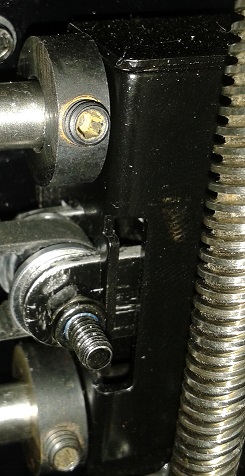

- Grinded Bar Locks

- resized bar locks.jpg (76.38 KiB) Viewed 14439 times

Grinded Bar Locks

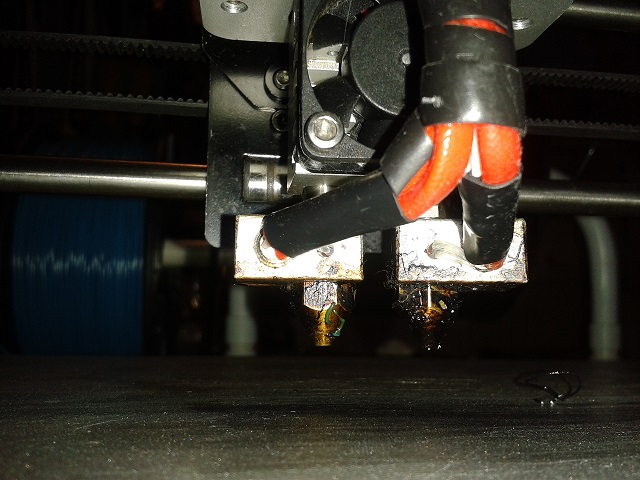

- Dual Print Head

- Dual Printhead.jpg (113.73 KiB) Viewed 14439 times

Dual Print Head

Re: M201 - GTM32 Suggestions & Questions

Posted: Tue Jul 05, 2016 8:46 am

by syossi2

Thanks

So you install the dual head firmware? The old one that here on the website?

Yossi

Re: M201 - GTM32 Suggestions & Questions

Posted: Tue Jul 05, 2016 1:33 pm

by greeffbf

Yes, it is called GTM32_Dual.zip and was posted by Mark.

To add z-axis max end stop.

Control ->

Printer Settings ->

Move right down to end stops, select z-max end stop. try the settings. Remember end stop will only work if axis max is greater than end stop position.

Re: M201 - GTM32 Suggestions & Questions

Posted: Tue Jul 05, 2016 1:59 pm

by syossi2

so you buy the mk8 dual head?

Re: M201 - GTM32 Suggestions & Questions

Posted: Tue Jul 05, 2016 2:35 pm

by greeffbf

No, I bought Two hot ends (the smallest I could get), Two nozzles, Two thermisters and Two 24Volt heaters in order to swap back when I want.

Just remove the last aluminum block 2 into 1. And assemble this. Easy to revert back to 2 in 1 out.

The biggest secret is setting the two heads very accurate same distance from print bed(Main reason why I replaced flexible couplings and lead screws).

Then in Slic3er you specify the offset of the two heads, there is a nice STL file with 4 checker squares you can use to fine tune and play with retract of fillament etc.. Can't remember the name now.

Cheers

Francois