Page 1 of 1

Nozzles levelling on g2s pro

Posted: Fri Oct 07, 2016 9:10 pm

by AndrewS

Hi

I've assembled a G2s pro, and everything is ok.

I can print perfectly with first extruder, but I don't understand how to bring the second nozzle level with the first one.

The instructions say to loose the top nut and screw the barrel. The problem is that after a 1/4 turn the barrel of the second extruder collides with the barrel of first noozle, and I can't rotate anymore.

There's a video or something else that explain the procedure?

Thanks

Andrea

Re: Nozzles levelling on g2s pro

Posted: Sat Oct 08, 2016 3:23 pm

by William

AndrewS wrote:Hi

I've assembled a G2s pro, and everything is ok.

I can print perfectly with first extruder, but I don't understand how to bring the second nozzle level with the first one.

The instructions say to loose the top nut and screw the barrel. The problem is that after a 1/4 turn the barrel of the second extruder collides with the barrel of first noozle, and I can't rotate anymore.

There's a video or something else that explain the procedure?

Thanks

Andrea

Hi,Andrea

Yes you can attach a video or some clear pictures to show it(have access to Youtube).

Re: Nozzles levelling on g2s pro

Posted: Mon Oct 10, 2016 2:47 pm

by AndrewS

hi!

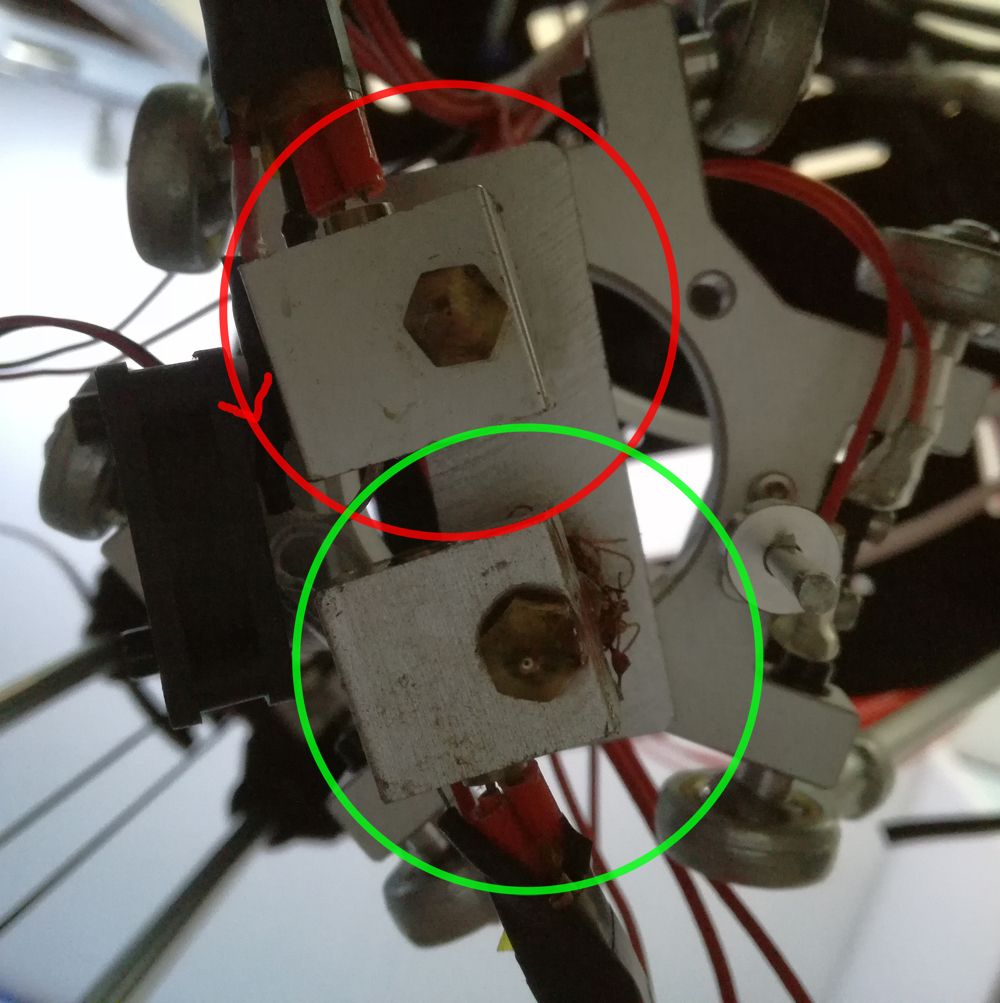

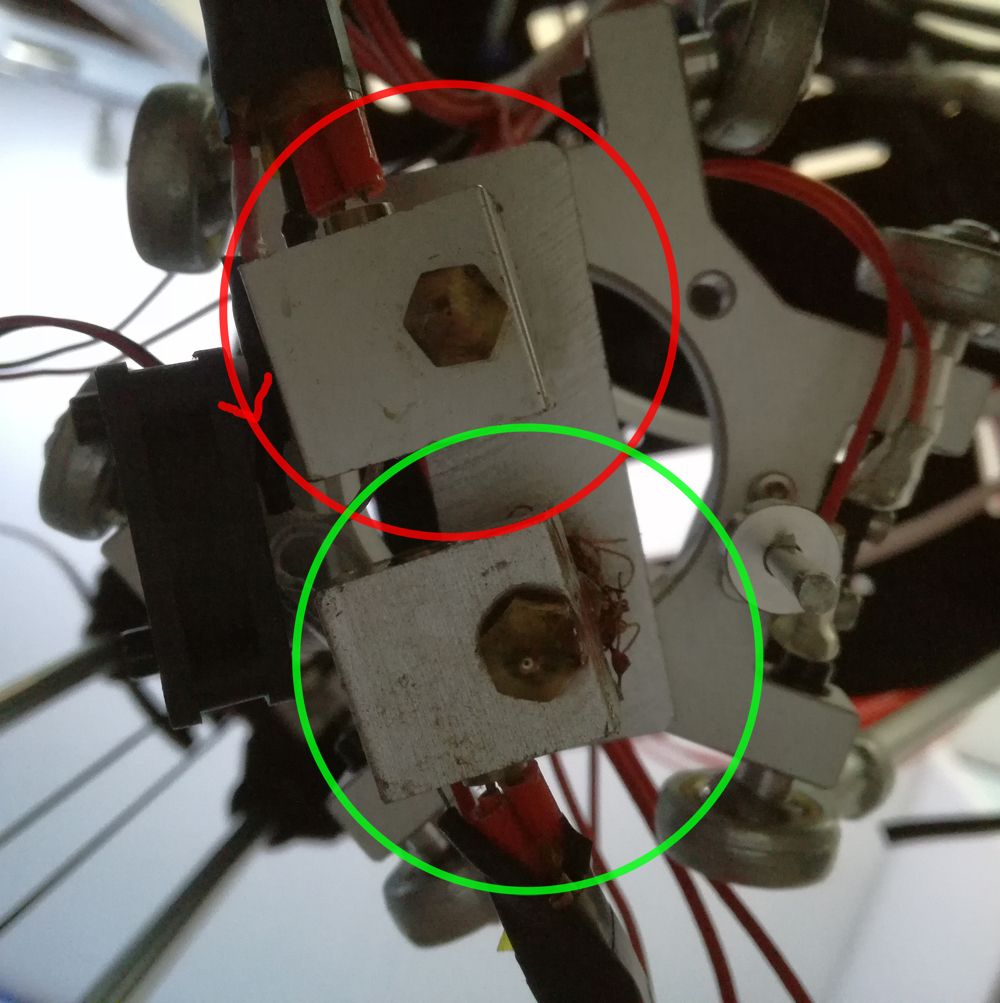

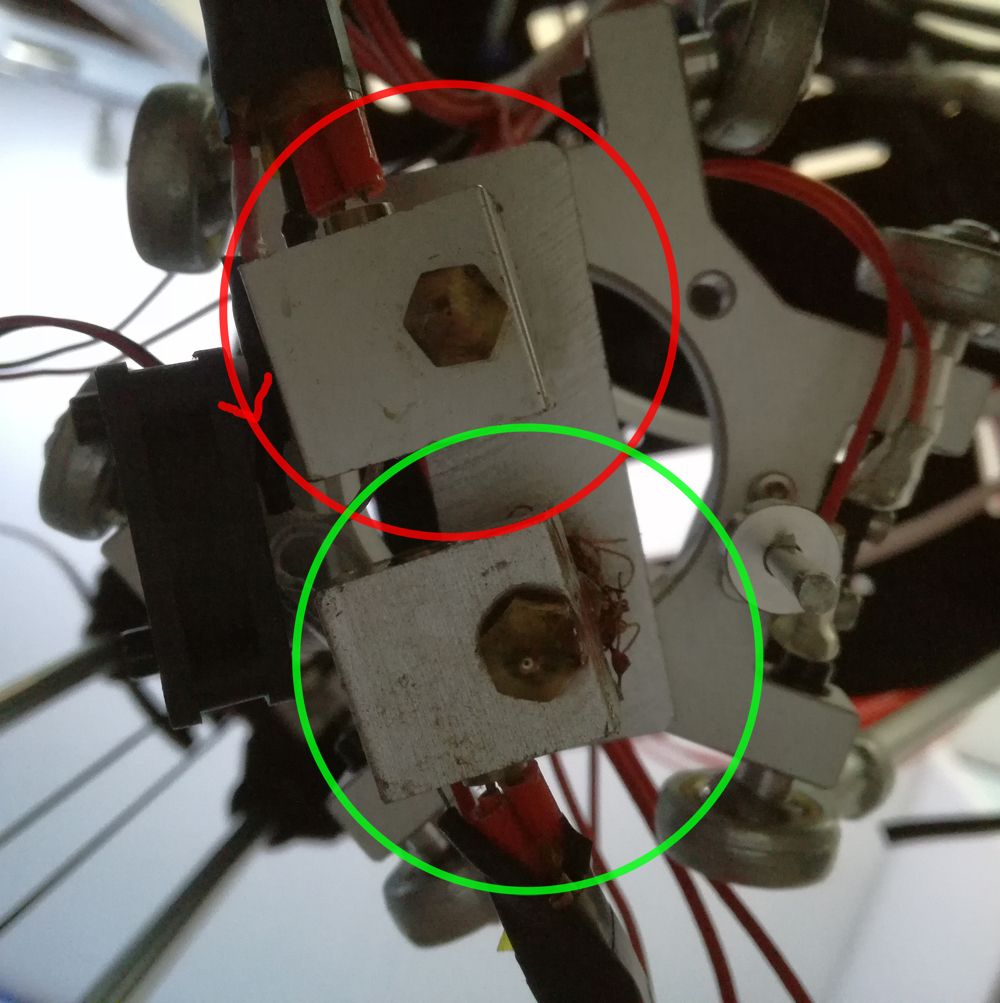

For now I've attached a pic.

As you can see if I rotate the blocks, over a certain angle the edge of the block collides with the other one, is not much but enough to prevent more rotation.

Re: Nozzles levelling on g2s pro

Posted: Mon Oct 10, 2016 5:45 pm

by William

AndrewS wrote:hi!

For now I've attached a pic.

As you can see if I rotate the blocks, over a certain angle the edge of the block collides with the other one, is not much but enough to prevent more rotation.

1.Have you leveled the hotend before you

level the bed? You can adjust the M6 nut to adjust the hight of the hotend.

- Catch(07-19-16-0(10-10-17-38-31).jpg (48.55 KiB) Viewed 14636 times

2.How to calibrate the whole bed? In fact, you can move the nozzle to (0,0,0) first, then move it horizontally to

the further side of the bed, check the distance between the nozzle and the bed, then you can adjust the M3x50mm

screw under the bed to make the nozzle just touch the bed.

Re: Nozzles levelling on g2s pro

Posted: Tue Oct 11, 2016 10:14 pm

by AndrewS

The calibration procedure is clear, no problem

I calibrated the printer with the first hotend, the problem is that I can't bring the second at the same eight with the first.

After unscrewing the M6 nut I have to rotate more than 1/2 turn the block to bring it lower, but I don't have the space to rotate so much because the block of hotend 2 touches the hotend 1 block.

Andrea

Re: Nozzles levelling on g2s pro

Posted: Wed Oct 12, 2016 4:53 pm

by William

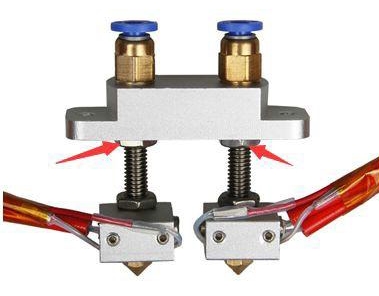

You can unscrew the 4 little screws(see the pictures) with a tool on the two side of the block first,then it's free to move the barrel(nozzle throat) up and down.

So you can adjust the position.

- 1.jpg (61.15 KiB) Viewed 14621 times

- 2.jpg (48.63 KiB) Viewed 14621 times

Re: Nozzles levelling on g2s pro

Posted: Wed Oct 12, 2016 5:02 pm

by AndrewS

Thanks I'll try!

Maybe should be explained better int he manual

Re: Nozzles levelling on g2s pro

Posted: Wed Oct 12, 2016 5:07 pm

by William

Ok,then let know how it goes plz.

Re: Nozzles levelling on g2s pro

Posted: Tue Jan 03, 2017 10:14 am

by lar3ry

I have the same problem as AndrewS.

I have the aluminum block, but there are no screws in it.

I can loosen the two nuts, and turn the barrel by hand, but of course, the end in the block screws out, and the end in the heater/nozzle block screws in, keeping the nozzle height the same.

Are the set-screws in your illustration tightened againt a smooth surface on the barrel or against a threaded part?

I suppose I could try disassembling/reassembling both units, hoping that I can get them so the nozzles are equidistant from the block, but that seems somewhat hit-and-miss.

Perhaps I could order a new block from Geeetech, or perhaps just print one and shield it better from the heat.

I can envision a more simple block with two unthreaded holes for the mounting screws (using nuts), and two unthreaded holes for the barrel, using nuts to keep it in place. But then how do I secure the filament entry thing?

Any other ideas?